Compressed Air Dryers & Filters

Bi-State Compressor is proud to offer Quincy and Deltech air dryers and filters to meet the needs of your facility. Designed to remove moisture from compressed air, these air dryers are manufactured to precise standards and represent the cutting edge in drying technologies.

As compressed air cools, water vapor condenses and needs to be removed to prevent moisture and other harmful substances from damaging industrial processes. At Bi-State Compressor, we offer a complete array of products to keep your equipment running smoothly, including:

- Refrigerated dryers

- Dessicant dryers

- Standard filtration: Particulate, Coalescer, and Absorber

At Bi-State Compressor, we offer the most innovative, reliable, and economical solutions for your industry. We’re happy to discuss your facility’s specific requirements and give you the best equipment available on the market today. If you need assistance determining which air dryer and filter system is right for your business, please call us at 636-349-8333 or fill out our contact form. We’re happy to help.

Quincy

The performance you demand. The reliability you can count on. Bi-State Compressor offers a variety of Quincy refrigerated air dryers and desiccant air dryers, as well as filters for effective removal of contaminants in your compressed air systems. Learn more about these products:Learn MoreRotary Screw Air Compressors

Refrigerated Dryers

Quincy Refrigerated Air Dryers purify compressed air by chilling it to approximately 37°F. This causes entrained moisture to condense. Condensed moisture carries airborne dirt and oil to the separator where it is removed from the air stream by an automatic drain.

QPNC Series

QPNC Series

Quincy QPNC Non-cycling dryers from 10 to 3000 cfm come standard with the most energy efficient ZERO LOSS DRAINS. These units use a two stage heat exchanger to maintain consistent dew points and are best suited to smaller systems with fairly constant loads. Freeze-ups are prevented, capitalizing on optimal performance.

• Integrated Moisture Separator

• Five step centrifugal separation

• 10-Year Heat Exchanger Warranty

QPNC Series

The QED and QPCD Series

The QED and QPCD Series

These units save energy by cycling the refrigeration on and off in response to demand and therefore are the most efficient drying technology available. A three-stage heat exchanger system is employed to provide the cold storage necessary for the operation.

• 35°F dewpoint

• 10 – 4,000 cfm

• 150 psig max

The QED and QPCD Series

QRHT Series

QRHT Series

QRHT Series Total Air System High Temperature Dryers integrate five different components that perform separate functions. An air-cooled aftercooler, refrigerated dryer, moisture separator, Zero Loss drain, and coalescing filter. These five components work in harmony to ensure clean dry, filtered compressed air.

• 180ºF Inlet Temperature

• 3-in-1 Design

• Eliminates Water, Oil and Dirt from Air

• Prevents Damage to Pneumatic Tools

• Fewer Finished Product Defects

• Prevents “Fisheye” Paint Splotches

• Reduces Operational Downtime

• Increase Profitability and Productivity

• Eliminates Air Line Purging

QRHT Series

Desiccant Dryers

Quincy desiccant dryers provide air purification from -40°F PDP down to -100°F PDP. These dryers are built and designed to provide the smallest footprint possible while ensuring maximum performance. Quincy desiccant dryers have ASME and CRN designed pressure vessels standard. Also, standard with the desiccant dryers is a 2-year package warranty and a 5-year valve warranty.

QHD Heatless Desiccant Dryer

QHD Heatless Desiccant Dryer

These dryers use a small portion of the dried compressed air to regenerate the off-line tower. The QHD series feature a low initial cost, a moderate operating cost and a low maintenance cost.

• -40° to -100°F dewpoint

• 100 – 3,400 cfm

• 14% purge

• Microprocessor control

QHD Heatless Desiccant Dryer

QDHP Heated Purge Desiccant Dryer

QDHP Heated Purge Desiccant Dryer

These dryers use half the compressed air to regenerate the offline tower than the comparative heatless series. The initial setup costs are moderate and its operating costs and maintenance costs are low. This series can be purchased with the optional Quincy MicroBurst Regeneration (MBR) system, the only full-load energy saver available for use with heated purge desiccant air dryers. The MBR cuts purge requirements in half and greatly reduces heater “on” time. When equipped with the Quincy MBR, our Heated Purge dryers use 50% less energy. ROI can be realized within 5 months, depending on dryer size and local power costs.

• -40° to -90°F dewpoint

• 100 – 3,100 cfm

• 3.5% to 7% purge

• Low-watt density heaters

QDHP Heated Purge Desiccant Dryer

QDBP Blower Purge Dessicant Dryer

QDBP Blower Purge Dessicant Dryer

These dryers combine heat with forced ambient air for regeneration. The initial costs are relatively high while the operating and maintenance costs are moderately low.

• +10° to -40°F dewpoint

• 300-3,400 cfm

• 2% Average Purge

• NEMA 4

QDBP Blower Purge Dessicant Dryer

QMOD Heatless Modular Desiccant Dryer

QMOD Heatless Modular Desiccant Dryer

These compact dryers use a small portion of dried compressed air to regenerate the offline tower. The initial costs of these systems are low, as is its maintenance costs while the operating costs are moderate.

• -40°F to -100°F dewpoint

• 8 – 365 cfm

• 18% purge

• CRN Approved

QMOD Heatless Modular Desiccant Dryer

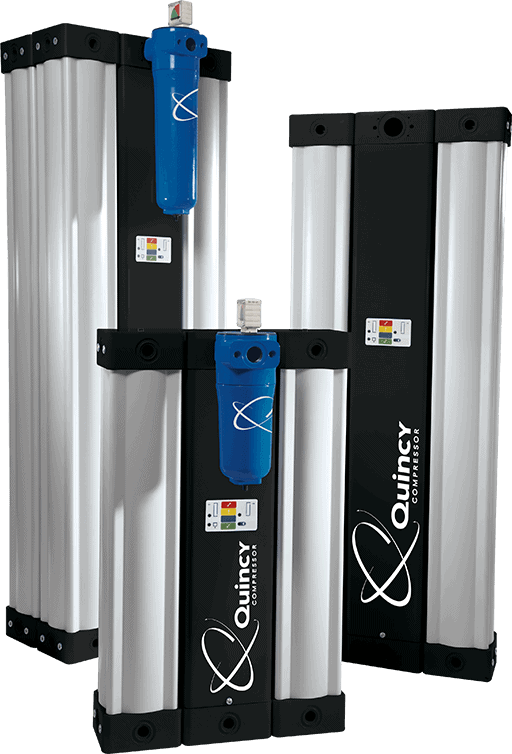

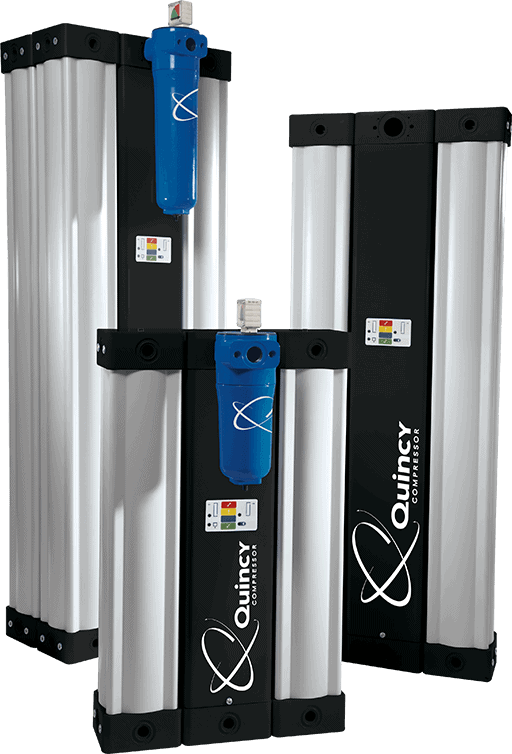

Standard Filters

Quincy’s Standard Filtration lineup consists of the three most common types of filters used in compressed air systems: Particulate, Coalescer and Absorber. Aluminum housings with threaded NPT connections are used for flows up to 1530 cfm and steel housings with flanged connections are used for flows up to 16,500 cfm.

Quincy DCN and QPF Series

Quincy DCN and QPF Series

Particulate/Coarse Coalescers are designed to remove solids, burnt oil and bulk liquids.

Quincy DCN and QPF Series

Quincy CSN and QMF, CPN and QCF Series

Quincy CSN and QMF, CPN and QCF Series

Coalescers remove various levels of liquid aerosols and mist.

Quincy CSN and QMF, CPN and QCF Series

Quincy ACN and QAF Series

Quincy ACN and QAF Series

Activated Carbon Absorbers remove vapors and odors.

• 10 scfm to 16,500 scfm

• 230 psig max. working pressure for threaded filters

• 150 psig max. working pressure for flanged filters

• Aluminum housing (1⁄2” to 3” NPT)

• Steel housing (3” to 12” FLG)

Quincy ACN and QAF Series

Deltech

Deltech is known for being the first in many air compression technologies, such as the first multistage coalescing filter to remove oil, dirt and water in a single unit. Deltech sets the standard for the next generation of compressed air treatment products. Bi-State Compressor offers a selection of Non-Cycling Refrigerated and Twin Tower Regenerative Desiccant dryers. Coalescing, Particulate, and Process Filters from Deltech.

Deltech Refrigerated Air Dryers

Refrigerated air dryers work by chilling the air to a temperature that causes the moisture in the air to condense and form droplets. This moisture and any contaminates contained therein can be separated from the air steam and discharged from the dryer. These dryers all have the same basic components to operate; a refrigeration system, heat exchanger, separator and drain. Although this technologies does not offer as low of a dew point as other dryers, this type of air dryer is quite popular due to their low initial capital costs, relatively low operating costs and low maintenance costs. They are quite versatile for many industries as the dew point range is well within many general industrial air plant applications. The Deltech line of refrigerated dryers is specifically engineered for applications above the freezing point of water, each series is crafted to meet your compressed air treatment requirements. These units are equipped to handle flows ranging from 10 - 3000 scfm (17 - 5097 nm3/h) and are tailored to operate across multiple applications. All Deltech refrigerated dryers incorporate environmentally friendly refrigerants and hermetically sealed refrigeration compressors to guarantee reliability for the life of your unit. They also utilize fully automatic condensate drain valves tp ensure the lowest possible dew point under all rated design conditions - without freeze-ups, saving energy and adding value to your bottom line!

Refridgerated Air Dryers

Refridgerated Air Dryers

HG Series and HGE Series

10-500 scfm (70-850 nm3/h)

10-500 scfm (70-850 nm3/h)

Refridgerated Air Dryers

High Inlet Temperature Air Dryers

High Inlet Temperature Air Dryers

HTD Series

20-125 scfm (34-212 nm3/h)

20-125 scfm (34-212 nm3/h)

High Inlet Temperature Air Dryers

Energy Saving Refrigerated Air Dryers

Energy Saving Refrigerated Air Dryers

DES Series

90-675 scfm (153-1148 nm3/h)

HYDROGUARD® HGD & DES Series

100-3000 scfm (170-5097 nm3/h)

90-675 scfm (153-1148 nm3/h)

HYDROGUARD® HGD & DES Series

100-3000 scfm (170-5097 nm3/h)

Energy Saving Refrigerated Air Dryers

Deltech Desiccant Air Dryers

The word desiccant air dryer encompasses a broad range of dryers. Regenerative dryer and twin tower dyer are other terms used to describe the same types of machines. Compressed air is passed through a pressurized vessel with two columns or towers. These towers are filled with materials such as activated alumina, silica gel, a molecular sieve or other absorbent or desiccant material, which attracts the moisture from the compressed air. The desiccant works to bring the pressure dew point of the compressed air to a level in which water will no long condense. In short the role of a desiccant dryer is to remove as much water from the air as desired in the most energy efficient manner possible. Deltech has been at the forefront of innovation and development in the desiccant dryer technologies. These energy efficient designs offer maximum value across a range of flow rates to provide flexibility, safety and reliability to meet all of your compressed air needs.

Every Desiccant Dryer contains these quality features: • Highly hygroscopic desiccants combine spherical uniformity with superior crush strength to deliver stable dew point control and low dust migration• Process quality switching valves deliver consistent repeatability to ensure system integrity and long component life cycles

• Precision timing circuits control process valve sequencing protocols to deliver optimum dew point stability and energy efficiency

• Calculated desiccant bed construction ensures ideal tower velocities to adsorb moisture, stabilize dew points, and prevent bed movement

• Spare muffler(s) are included on all models and sizes

Pressure Swing Heatless Desiccant Air Dryers

Pressure Swing Heatless Desiccant Air Dryers

The WM Series

5-25 scfm (850-7306 nm3/h)

5-25 scfm (850-7306 nm3/h)

Pressure Swing Heatless Desiccant Air Dryers

Heatless Desiccant Air Dryers

Heatless Desiccant Air Dryers

HCS Series, HCL Series and HCT Series

40-5400 scfm (68-9175 nm3/h)

40-5400 scfm (68-9175 nm3/h)

Heatless Desiccant Air Dryers

Externally Heated Desiccant Air Dryers

Externally Heated Desiccant Air Dryers

RP Series

250-3200 scfm (425-5437 nm3/h)

250-3200 scfm (425-5437 nm3/h)

Externally Heated Desiccant Air Dryers

Blower Purge Desiccant Air Dryer

Blower Purge Desiccant Air Dryer

ZP Series

500-4300 scfm (850-7306 nm3/h)

500-4300 scfm (850-7306 nm3/h)

Blower Purge Desiccant Air Dryer

Heat of Compression Desiccant Air Dryers

Heat of Compression Desiccant Air Dryers

HOC Series

3750-10000 scfm (6371-169990 nm3/h)

3750-10000 scfm (6371-169990 nm3/h)

Heat of Compression Desiccant Air Dryers

Compressed Air Filtration Technologies

Bi-State Compressor is proud to offer Del-Monox air purifiers and other air filtration technologies to meet the needs of your facility. When used as directed, Del-Monox purifiers supply air that meets OSHA Grade D and Canadian Standards Association (CSA) maximum allowable contaminant levels for compressed breathing air. The quality of the inlet air to the compressor will affect the efficiency of the breathing air purifiers. The compressor intake must be located in an environment that is not oxygen deficient and does not contain excessive levels of carbon monoxide. To meet the OSHA standards of 10 ppm maximum allowable concentration of CO at the system outlet, CO at the inlet must not exceed 200 ppm. To meet CSA standards of 5ppm maximum concentration at the outlet, the inlet concentration must not exceed 100 ppm of CO. In order to reduce the levels of CO, the Del-Monox system makes precise use of technology, utilizing catalytic conversion towers to change CO into CO2. This is a process that can be hampered when the relative humidity in the airstream increases, which is why every Del-Monox system is built with proven compressed air dehydration techniques to protect the catalytic converter from moisture.

The engineered system uses six stages of purification to ensure that air output achieves the required specified air quality levels.

- Step 1: The one micron general purpose filter removes both solid and liquid contaminates.

- Step 2: The 0.01 micron high efficiency coalescing type oil removal filter removes virtually all liquid oil aerosols.

- Step 3: The Deltech Pressure Swing Regenerative Desiccant Dryer reduces the moisture levels to ensure the proper effective operation of the catalyst bed.

- Step 4: The Catalytic Converter lowers the concentrations of CO by converting it to CO2.

- Step 5: A particulate afterfilter removes contaminates one micron and larger from the airstream.

- Step 6: Finally, the activated carbon filter removes oil vapor and any undesirable odors from the airstream.

Compressed Air Filter

Compressed Air Filter

300 Series

20-1500 scfm (34-2549 nm3/h)

DF Series

20-21250 scfm (34-36104 nm3/h)

20-1500 scfm (34-2549 nm3/h)

DF Series

20-21250 scfm (34-36104 nm3/h)

Compressed Air Filter

Color Change Compressed Air Filters

Color Change Compressed Air Filters

100 Series

Color Change Compressed Air Filters

Low Pressure-Drop Oil Coalescer to 0.001 ppm

Low Pressure-Drop Oil Coalescer to 0.001 ppm

810 Series

Low Pressure-Drop Oil Coalescer to 0.001 ppm

Mist Eleminator

Mist Eleminator

ME Series

0.5 ppm Oil Removal

0.5 ppm Oil Removal

Mist Eleminator